Solar at the Bullitt Center

(C) John Stamets

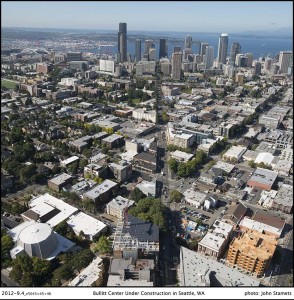

Solar can pencil out in Seattle. Position the photovoltaic panels to receive the long days of summer sun in our region and enough energy will be generated to provide clean energy and potentially provide a good return on investment. Seattle receives slightly more solar radiation than Germany, a country well on its way to meeting all energy needs through renewables by 2050. To encourage naysayers about solar in our region, note that solar panels operate more efficiently in cooler climates, and produce energy even under cloudy skies. Seattle has seen explosive growth in the installation of solar arrays, with 600 installations in the last three years.

Solar power is clean and comes from a reliable and free source, the sun. Renewable energy and energy efficiency can help reduce carbon emissions and slow the rate of climate change, and can reduce our dependency on foreign fossil fuels. Solar power decreases the carbon footprint of a building and increases the revenue stream by lowering utility bills. (It takes roughly three years for the carbon footprint of producing a PV panel to be offset.) Energy produced by PV panels is available at the time of day when energy is most expensive to purchase and demand is highest. This solar energy production increases the peak load generating capacity of the utility and saves it from turning on expensive supplemental systems during peak demand. The average price of solar panels dropped by 50% in the last year and the number of solar installations doubled (from 887 megawatts in 2010 to 1,855 megawatts in 2011) according to the Solar Energy Industries Association.

(C) John Stamets

The Renewable Portfolio Standard (RPS) requires that utilities produce a specified percentage of their electricity from renewable energy sources, including solar, wind, biomass, and geothermal. In 2006 Washington State approved the Energy Independence Act, I-937, to improve the state’s Renewable Portfolio Standard. Local utilities serving more than 25,000 customers are required to get at least 3% of their electricity from eligible renewable sources as of January 1, 2012; at least 9% by January 1, 2015; and at least 15% by January 1, 2020.

The state of Washington gets 10% of its renewables from large wind installations and is the second largest adopter of wind in the country with three large wind installations. But wind needs large scale to be efficient. Solar, on the other hand, can operate efficiently on a small scale. The future of wind installations is up for grabs when the wind power production tax credit, which has been in place since 1992, expires at the end of this year.

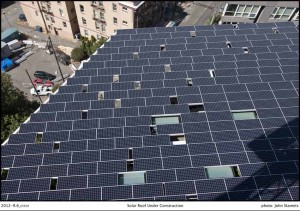

The Living Building Challenge requires a building to meet Net Zero Energy, meaning it must produce all the energy it needs annually on site through renewable energy production. This was the driving criteria for all the design decisions of the Bullitt Center. After reviewing all the options for on-site renewable energy, solar electricity made the most sense and was the strategy chosen.

Steven J. Strong, founder of Solar Design Associates and a pioneer in solar design in this country for the past 35 years, was on board this project from the onset. At the end of the first day of a design charrette with 50-some architects, engineers, and environmental professionals, Steven and Craig Curtis (of the Miller Hull Partnership) met through the evening to hammer out a conceptual design for the Bullitt Center. The number one issue was how to solve the energy balance. This became a major form driver for the project. Two massing types were proposed: an atrium or two bars. Step two was calculating that roughly 14,000 square feet of PV panels could fit on the building. This translated to a maximum energy production of ~250,000 kiloWatt hours (kWh) on average per year, which equated to an EUI (Energy Use Intensity) requirement of less than 20 kBtu/ft². From this work they presented a sketch as a baseline for the next day’s charrette. This early collaboration between Craig Curtis, the partner in charge of design, and Steven Strong, the solar expert, established a conceptual framework for the Bullitt Center that was a constant throughout the design process of the building.

(C) John Stamets

Over 50 solar array configurations were modeled in Rhino and Grasshopper, two modeling software programs, to test the power production and impact to daylighting. The solution you see on the roof now was found to be the most cost effective and productive. The benefit of the low-slope array at the Bullitt Center is that is it positioned to focus on summer energy collection, when there are long days of mostly overhead sun at our latitude. Although the panels are operating at less than optimum output because of their low angle relative to the sun, more of the highly efficient modules are able to fit within the available area and so the maximum amount of energy possible for the site can be produced. If you tilt a panel to a higher angle, you bring in structural issues since the angle increases both structural loads and wind loads. Fewer panels can be installed because of row to row shading, where one panel shades another behind it, so the spacing must be increased between rows of panels, or a larger plane of panels requires more substantial structure. Also, the loss from reducing the tilt of the panels from their optimum angle of ~32.5 degrees is surprisingly small, at only just about 10%. In Seattle the same array at a 90 degree tilt would operate at about 60% efficiency; at 0 degree tilt the efficiency would be ~86%, with the panel tilt at the Bullitt Center of 5 degrees the efficiency is ~90% of optimum, with the added benefit of greater production area available than would be possible at a higher tilt.

There are 575 PV panels on the roof of the Bullitt Center, at 425 watts per panel, manufactured by Sunpower Corporation of San Jose. The Living Building Challenge group granted an exception to the sourcing radius requirement because of the need to purchase high-efficiency PV panels. Here is the sourcing of the components of the panels: the EVA was sourced from North America, the cells from the Philippines, the wires from Switzerland, the frames from Malaysia, the glass from North America, and the final assembly occurred in California. On the roof of the Bullitt Center there are 13,400 square feet of solar collection area and the photovoltaic array’s DC (direct current) rating is 244.38kW. There are 19 string inverters located under the array in the designated mechanical area, along with an AC Combining Panel Board, a Utility Required Disconnect, and the other required building fire safety systems. The solar array is designed by Solar Design Associates of Harvard, MA. It is being installed by Northwest Wind and Solar of Seattle. The crew from NW Wind and Solar said they had never done anything on this scale before. They were pleased that the install went smoothly, saying the only challenge was getting a feel for the innovative racking system.

The panels will get dirty, but rainfall will serve to rinse the panels. Having someone go up and manually clean the panels typically only makes sense on utility-scale ground-mount installations; on a project such as the Bullitt Center, manual cleaning can do more damage than good. The panels will get dirty and degrade on a cyclical basis. When dirty, they might lose 1 to 2% of their performance, but after a rain they will return to full functionality. Over the course of a year an equipment degradation of less than ½% is to be expected. Over 20 years a 10% degradation is the norm. The system life of the panels is 20 to 25 years, which assumes some regular maintenance. The inverters are expected to be updated every 12 years or so. The roof under the solar array is white, which in itself reduces the cooling load by about 15% not counting the solar PV shading. The fact that the panels are shading the roof itself doubles the lifespan of the roof.

(C) John Stamets

Along with challenges like fire access, skylights, the odd shape of the building, and the debate over the optimal panel tilt, the racking to support the PV panels on the roof of the Bullitt Center provided a unique challenge. Similar to the process of designing the heavy timber connections (mentioned in an earlier blog), members of the different disciplines gathered together to problem-solve. The contractor, architect, installer, engineer, and fabricator of the rails met to come up with a unique solution to the challenge of supporting the substantial array which cantilevers over the building on three sides (to face of curb on Madison and 15th and to centerline of alley). RF Stearns fabricated and installed the steel beams on the roof which support the aluminum racking system. The PV panels are attached to the aluminum racks, designed and fabricated by HatiCon Solar of Ontario, CA. Steel saddles were custom designed by Christian LaRocco of Schuchart, reviewed by the structural engineers at DCI Engineers of Seattle and fabricated by RF Stearns of Lake Oswego, OR. These saddles sit on the steel beams and receive the aluminum racking system. The saddles are a unique design and provide ease of installation and flexibility of placement. The steel saddles are set onto the beam by the solar installers. Then the rails are set into the saddles. The off-the-shelf aluminum extrusion rails have been flipped upside down and the panels are installed at 90 degrees to the normal rail connection. The panels are set into the rails, with the aid of suction cups on the underside of the panel to adjust their placement. Four points along the edges of the panel are directly T-bolted to the rail. In corner and edge wind zones there are eight T- bolt connections to the rail. The installers set two rows of rails and panels at a time. Once these panels are properly secured the steel saddles are bolted to the steel beam. The benefit to this steel saddle design is that is allows for adjustment on site during installation, insuring a precise layout. Northwest Wind and Solar coordinated the solar panel to aluminum racking connection, with close interface with Solar Design Associates.

A solar panel, also referred to as a module, contains photovoltaic cells made from silicon. The term photovoltaic combines “photo” (light) with “voltaic” (electricity): electricity, rather than heat, is generated from the UV rays of the sun. These cells contain chemically modified wafers of silicon to produce positively and negatively charged surfaces under a thin sheet of ultra-clear low-iron glass, ideally with an anti-reflective coating to capture the most light. When the photons of the sunlight beat down on these photovoltaic cells, the electrons are knocked off the negatively charged surface and are attracted to the positive side of the silicon cell. The now negatively-charged free electrons create an electric voltage whose potential can be collected and sent through wires to the inverters. The PV panels on the roof of the Bullitt Center are wired together into groups and the current from each group is sent over to its designated inverter, which transform the DC into 120/240 volt AC (alternating current). The Bullitt Center has 19 inverters for several reasons: reduced overall weight and structure required to support them, ease of maintenance, simplicity of future replacement, and redundancy (if one fails the others continue to work). After the inverters, all the circuits come together in the AC Combining Panel Board. From there the electricity travels down to the Utility Required Disconnect located in the bike storage room with easy access from the side alley and East Madison St. This is in a location where, in case of an emergency, a fire fighter can quickly turn off the system. From this point the current goes to the Main Electrical Panel.

(C) John Stamets

The building uses what it needs and the excess leaves the building, entering the utility grid. If the solar array produces more energy than is needed for the building, the excess goes out into the utility grid and the energy is credited to the owner. This is called Net Metering. For the Bullitt Center there will be a net energy outflow into the grid in the summer months, and in the winter months the building will pull energy off the grid, in order to reach the goal of an overall net zero sum over the course of a year. This energy production and use will be carefully monitored and dashboards showing the performance of this and other building systems will be available for the pubic to view in the building.

In the summer months when the solar array is producing more energy than the building needs, this excess power naturally goes to the nearest location requiring electricity (the nearest electric load). In a sense, there is the possibility of “infinite storage” for solar energy produced with a Net Metering local utility, where the utility grid is used as a virtual storage battery. However, the solar energy does not go somewhere to be stored, like with a battery, but is moved around the western power grid called the Western Interconnection as needed and is credited to the solar energy producer’s account. In actuality, on the scale of a local building solar array such as that at the Bullitt Center, the excess energy is consumed by immediate neighbors before making it out onto the greater distribution networks.

Incentives are available to help with the purchase and installation of solar systems. The developers of the Bullitt Center were able to take advantage of a 30% Federal grant to use towards the purchase of the solar panels. This grant option expired January 1st, 2012. However, there is still a Federal Tax Credit (due to expire in 2016) which offers a Federal Income Tax credit for up to 30% of the installation cost of a commercial solar energy system. This credit can be carried forward for up to 20 future tax years if needed. The State of Washington offers varying levels of electricity and production credits which expire in 2020. More credit is offered if the solar panels and inverters are made in Washington. Also, various utility companies in the state offer credits and low-interest loans to pay for installation of solar energy systems. Through June 30, 2013, there is a 100% rebate on any Washington State Sales and Use Tax paid for the installation of a solar system. The website dsireusa.org is a good resource for details on incentives and policies for renewable energy. The industry estimates that there is about a five year payback on a solar system with the current incentives and pricing.

(C) John Stamets

The true test of all this is when the Bullitt Center is up and running. The big challenge is accuracy of modeling. It’s one thing to model it – and another to live it. Other big challenges are to get all the systems right, to get them operating properly, and to get the user interface clear and correct. As Luke McKneally, project manager for the solar engineering, said when speaking about designing the solar array for the Bullitt Center, “There is no such thing as a net-zero building, only net-zero occupants”. Designers like those at Miller Hull Partnership and Solar Design Associates can design the “optimal machine”, but it remains up to the user to optimize. When not run properly and maintained, an energy-efficient design can be wasted.

Innovation and teamwork at the Bullitt Center created a grand solar array which will produce all the energy the occupants should need over the course of the year. The team is determined to set an example for others that renewables like solar can provide enough energy for a common building type like a six-story office building. As the American Solar Energy Society has noted, “Solar energy and energy efficiency are key to protecting the environment and growing the economy”. The Bullitt Center is giving us a building that will prove we can do it.