Timber Framing at the Bullitt Center

Connecting the Timber Frame at the Bullitt Center

It has been rewarding to watch as the timber and steel frame goes up on the Bullitt Center. It brings to mind several critical meetings back in the design phase of the project that serve as a good example of how the design team worked together on this project. Meetings typically involved the developer and owner, the contractor, the engineers and the architect. We worked collaboratively to solve some fairly complex conditions while simultaneously balancing the competing demands of performance and design with constructability and cost. What often began as constraints and sacrifices routinely developed into elegant solutions we are all proud of.

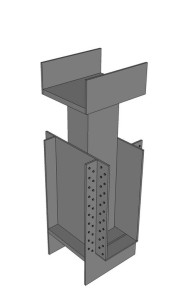

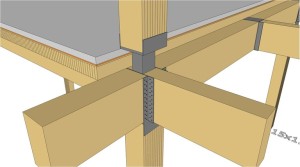

Fire proofing the connection

One of the great virtues of a heavy timber structural system is the fire proofing inherent in the sheer size of the wood members. We all know that wood burns, but it does so at a relatively slow and predictable rate. So, were there ever to be a fire in the building, the timber chars and burns slowly allowing plenty of time for occupants to vacate and the fire department to arrive. The steel connections that hold the timbers together are a potential weak pointbecause steel when heated begins to soften and, if not protected in some way, will fail. One method of protecting a steel connection is to conceal it within wood. This creates a virtually invisible connection that looks great but can be expensive and complex. Another method is to leave the connection exposed but paint it with a fireproof coating. This is also an expensive and time consuming proposition. The third option, and the one we settled on, is to design the connector in a way that the main girders bear directly on the timber columns that support them. In the event of a fire, even if the steel is weakened by heat, we still have timber bearing on timber and the beams will not fall. You’ll notice if you look at the connection carefully, that each of the four beams passes through the bucket connection and has about three inches of material bearing directly on the column below.

Anticipating the movement of wood

Another noteworthy aspect of the connection is the steel post standoff. A critical attribute of wood that architects and engineers must be aware of when designing a timber building is the fact that wood shrinks slowly over time and can be compressed if loaded perpendicular to the grain. If you’re not careful, your building can shrink up to half an inch per floor. This adds up quickly when you have multiple floors and makes it difficult to detail a high performance envelope. To avoid this issue we inserted a steel tube to connect the top of one timber column to the bottom of the next. Therefore, any radial shrinkage in the beams and girders will not impact the columns. The result is a timber frame building that should not shrink and settle over time.

Designing for constructability

The connectors we used were instrumental in facilitating ease of construction. Schuchart, the general contractor, was looking for a quick and efficient way to put the frame together onsite. Our system allowed for each beam to be lifted by crane and simply placed into the buckets without any temporary shoring or scaffolding. Framers then fasten the beams to the connectors. We elected to use a series of ¼” diameter SDS screws instead of the typical larger, bolted connections to save time and eliminate the need to pre-drill the beams. The screws can also be installed closer to the end of the beam than the bolts could be, which not only saves materials on the connector, but gives us a more elegant, minimal expression.

Win-win

The solution the team arrived at truly was a win-win for the project. The team was able to work together through all the competing constraints of constructability, cost and performance. We ended up with a unified family of connectors that are expressive of the forces and concepts that act upon them and help visually tell the story of how the building was put together.

For those interested in seeing technical details of the heavy timber design, you can see the plans here: Heavy Timber Details.